| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 148124 | 456406 | 2013 | 8 صفحه PDF | دانلود رایگان |

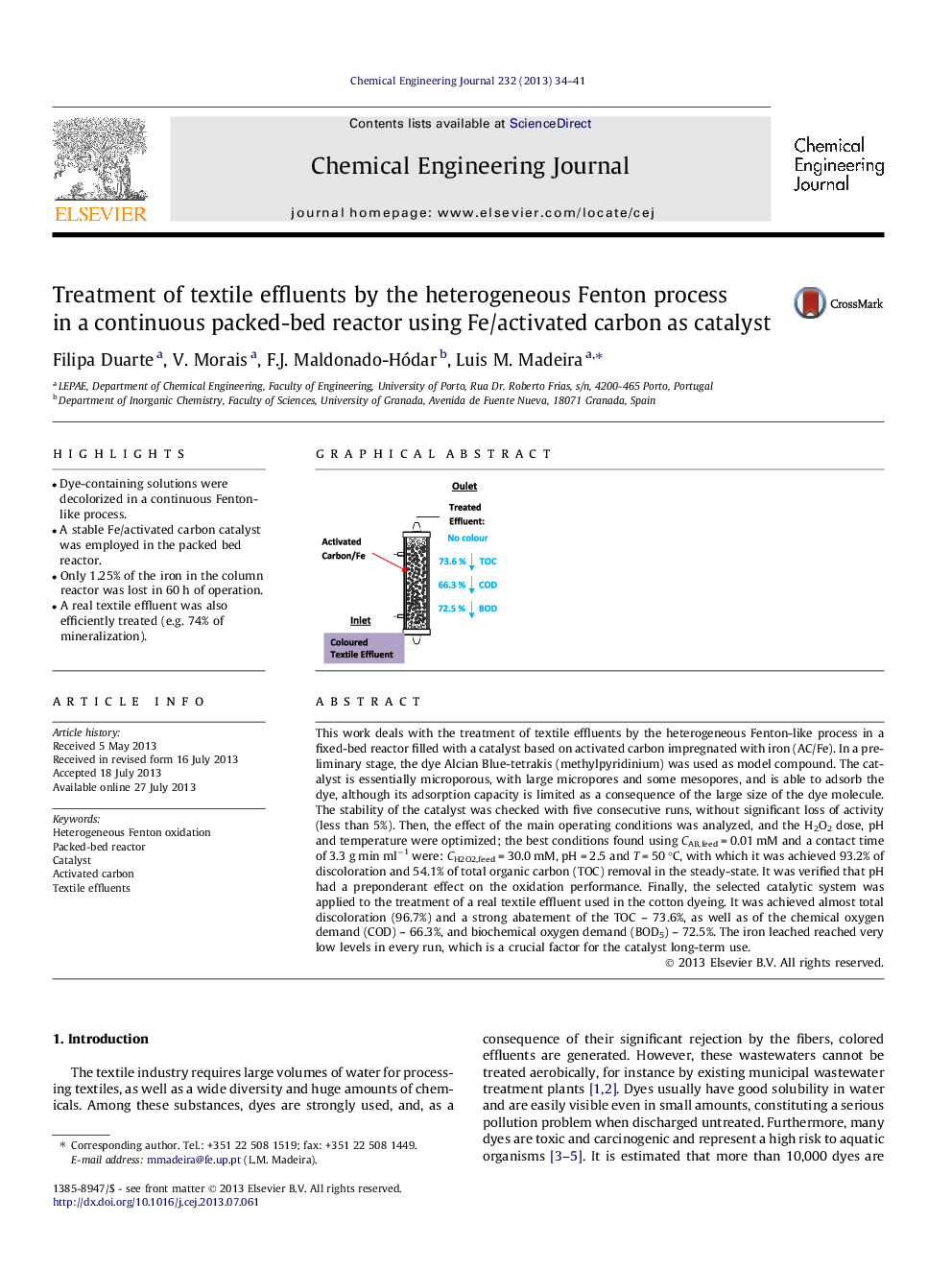

• Dye-containing solutions were decolorized in a continuous Fenton-like process.

• A stable Fe/activated carbon catalyst was employed in the packed bed reactor.

• Only 1.25% of the iron in the column reactor was lost in 60 h of operation.

• A real textile effluent was also efficiently treated (e.g. 74% of mineralization).

This work deals with the treatment of textile effluents by the heterogeneous Fenton-like process in a fixed-bed reactor filled with a catalyst based on activated carbon impregnated with iron (AC/Fe). In a preliminary stage, the dye Alcian Blue-tetrakis (methylpyridinium) was used as model compound. The catalyst is essentially microporous, with large micropores and some mesopores, and is able to adsorb the dye, although its adsorption capacity is limited as a consequence of the large size of the dye molecule. The stability of the catalyst was checked with five consecutive runs, without significant loss of activity (less than 5%). Then, the effect of the main operating conditions was analyzed, and the H2O2 dose, pH and temperature were optimized; the best conditions found using CAB,feed = 0.01 mM and a contact time of 3.3 g min ml−1 were: CH2O2,feed = 30.0 mM, pH = 2.5 and T = 50 °C, with which it was achieved 93.2% of discoloration and 54.1% of total organic carbon (TOC) removal in the steady-state. It was verified that pH had a preponderant effect on the oxidation performance. Finally, the selected catalytic system was applied to the treatment of a real textile effluent used in the cotton dyeing. It was achieved almost total discoloration (96.7%) and a strong abatement of the TOC – 73.6%, as well as of the chemical oxygen demand (COD) – 66.3%, and biochemical oxygen demand (BOD5) – 72.5%. The iron leached reached very low levels in every run, which is a crucial factor for the catalyst long-term use.

Figure optionsDownload as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 232, October 2013, Pages 34–41