| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 148731 | 456421 | 2013 | 9 صفحه PDF | دانلود رایگان |

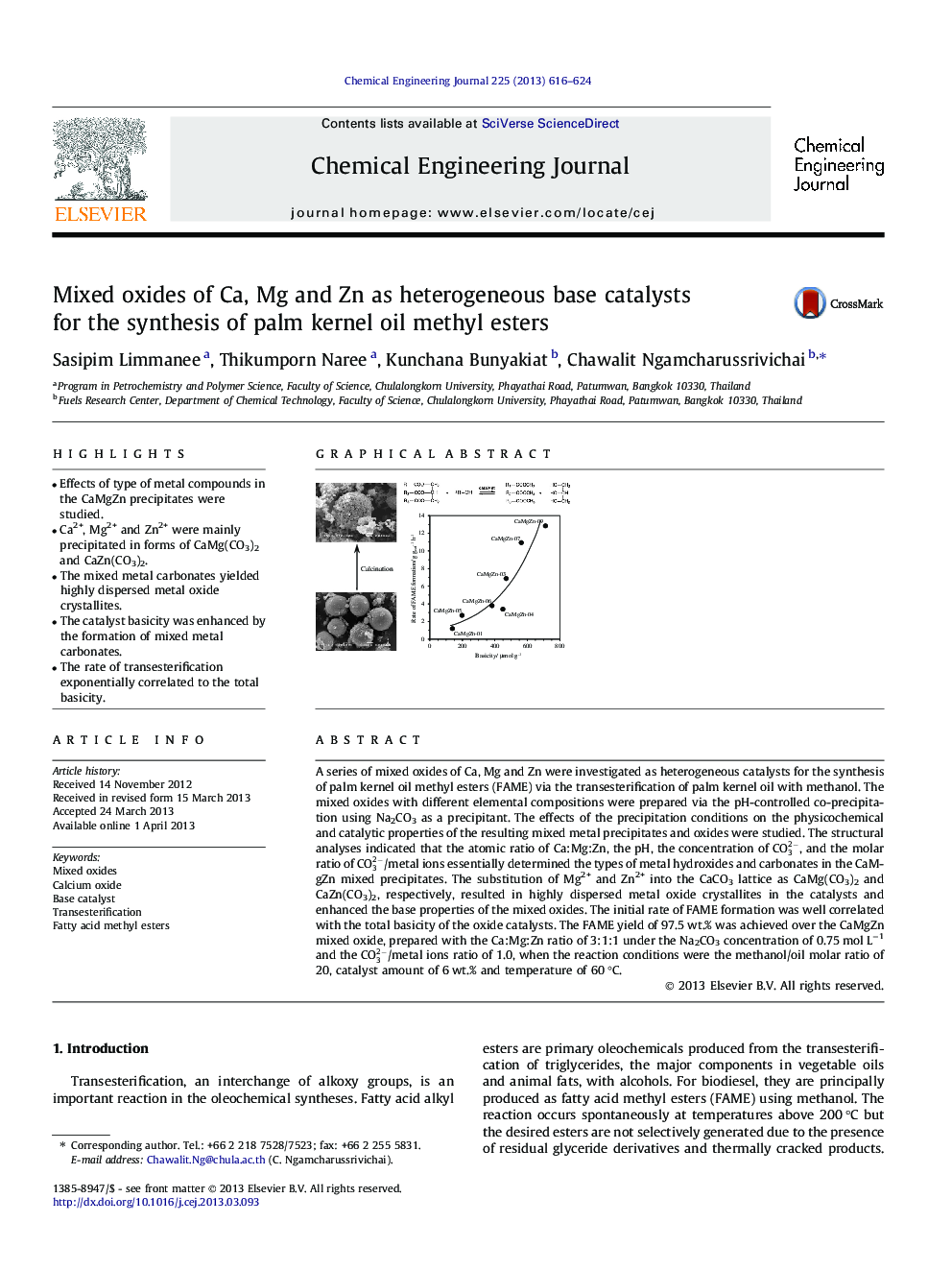

• Effects of type of metal compounds in the CaMgZn precipitates were studied.

• Ca2+, Mg2+ and Zn2+ were mainly precipitated in forms of CaMg(CO3)2 and CaZn(CO3)2.

• The mixed metal carbonates yielded highly dispersed metal oxide crystallites.

• The catalyst basicity was enhanced by the formation of mixed metal carbonates.

• The rate of transesterification exponentially correlated to the total basicity.

A series of mixed oxides of Ca, Mg and Zn were investigated as heterogeneous catalysts for the synthesis of palm kernel oil methyl esters (FAME) via the transesterification of palm kernel oil with methanol. The mixed oxides with different elemental compositions were prepared via the pH-controlled co-precipitation using Na2CO3 as a precipitant. The effects of the precipitation conditions on the physicochemical and catalytic properties of the resulting mixed metal precipitates and oxides were studied. The structural analyses indicated that the atomic ratio of Ca:Mg:Zn, the pH, the concentration of CO32-, and the molar ratio of CO32-/metal ions essentially determined the types of metal hydroxides and carbonates in the CaMgZn mixed precipitates. The substitution of Mg2+ and Zn2+ into the CaCO3 lattice as CaMg(CO3)2 and CaZn(CO3)2, respectively, resulted in highly dispersed metal oxide crystallites in the catalysts and enhanced the base properties of the mixed oxides. The initial rate of FAME formation was well correlated with the total basicity of the oxide catalysts. The FAME yield of 97.5 wt.% was achieved over the CaMgZn mixed oxide, prepared with the Ca:Mg:Zn ratio of 3:1:1 under the Na2CO3 concentration of 0.75 mol L−1 and the CO32-/metal ions ratio of 1.0, when the reaction conditions were the methanol/oil molar ratio of 20, catalyst amount of 6 wt.% and temperature of 60 °C.

Figure optionsDownload as PowerPoint slide

Journal: Chemical Engineering Journal - Volume 225, 1 June 2013, Pages 616–624