| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 257528 | 503591 | 2014 | 9 صفحه PDF | دانلود رایگان |

• Surface chemistry controls rheology in alkali-activated slag cements.

• Particle–particle interactions and gelation influenced by activator nature.

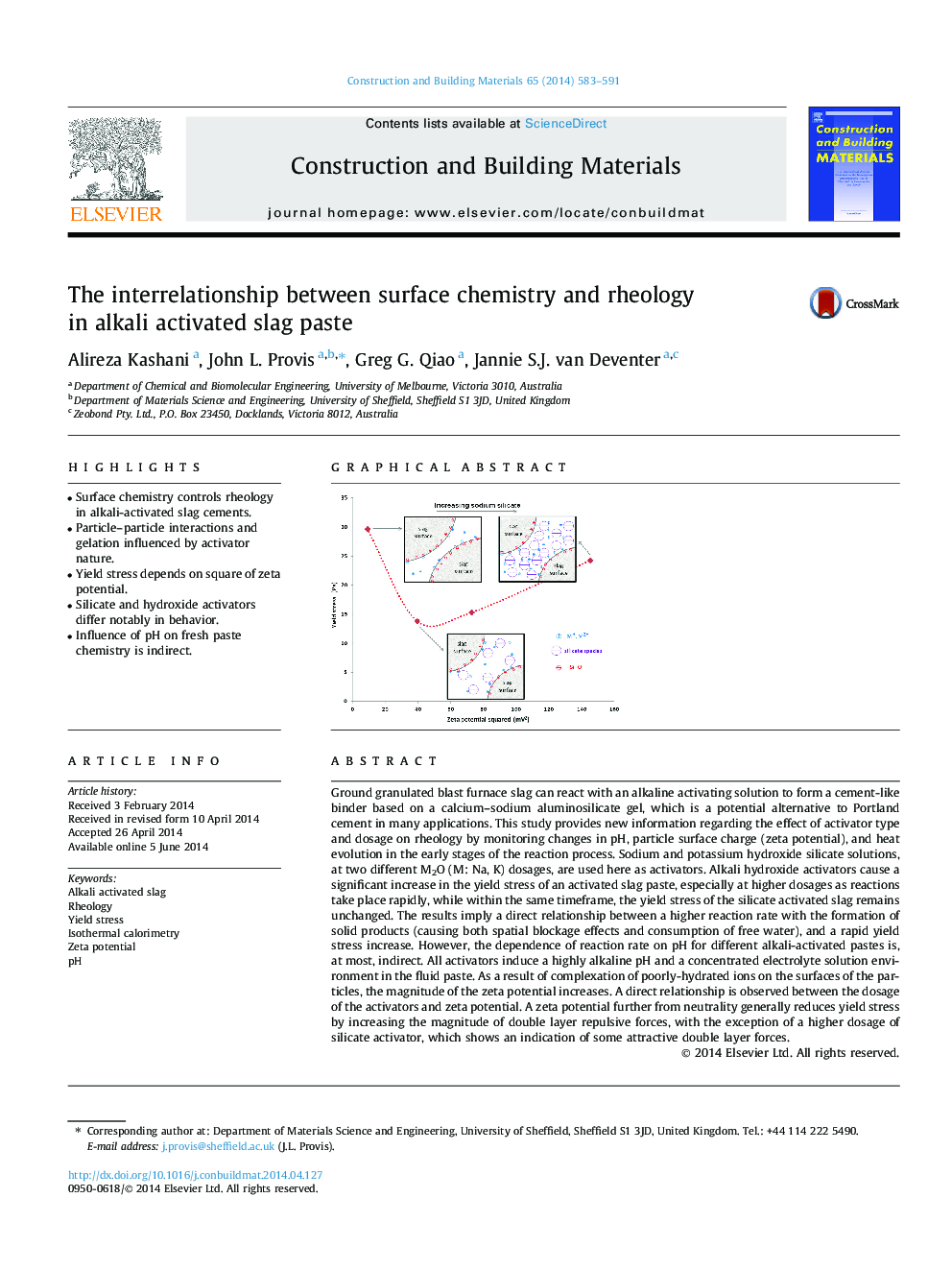

• Yield stress depends on square of zeta potential.

• Silicate and hydroxide activators differ notably in behavior.

• Influence of pH on fresh paste chemistry is indirect.

Ground granulated blast furnace slag can react with an alkaline activating solution to form a cement-like binder based on a calcium–sodium aluminosilicate gel, which is a potential alternative to Portland cement in many applications. This study provides new information regarding the effect of activator type and dosage on rheology by monitoring changes in pH, particle surface charge (zeta potential), and heat evolution in the early stages of the reaction process. Sodium and potassium hydroxide silicate solutions, at two different M2O (M: Na, K) dosages, are used here as activators. Alkali hydroxide activators cause a significant increase in the yield stress of an activated slag paste, especially at higher dosages as reactions take place rapidly, while within the same timeframe, the yield stress of the silicate activated slag remains unchanged. The results imply a direct relationship between a higher reaction rate with the formation of solid products (causing both spatial blockage effects and consumption of free water), and a rapid yield stress increase. However, the dependence of reaction rate on pH for different alkali-activated pastes is, at most, indirect. All activators induce a highly alkaline pH and a concentrated electrolyte solution environment in the fluid paste. As a result of complexation of poorly-hydrated ions on the surfaces of the particles, the magnitude of the zeta potential increases. A direct relationship is observed between the dosage of the activators and zeta potential. A zeta potential further from neutrality generally reduces yield stress by increasing the magnitude of double layer repulsive forces, with the exception of a higher dosage of silicate activator, which shows an indication of some attractive double layer forces.

Figure optionsDownload as PowerPoint slide

Journal: Construction and Building Materials - Volume 65, 29 August 2014, Pages 583–591