| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 6465935 | 1422958 | 2017 | 7 صفحه PDF | دانلود رایگان |

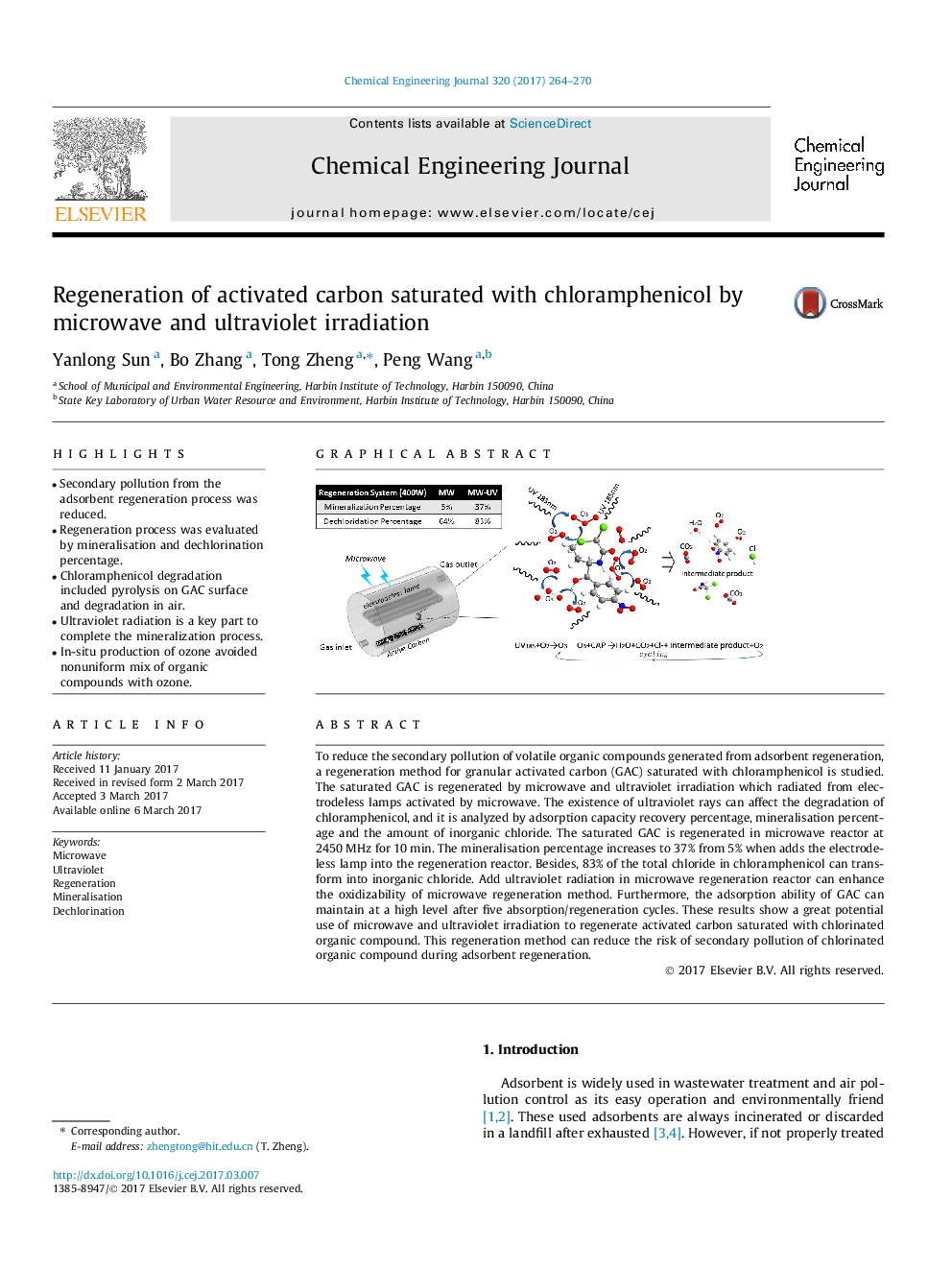

- Secondary pollution from the adsorbent regeneration process was reduced.

- Regeneration process was evaluated by mineralisation and dechlorination percentage.

- Chloramphenicol degradation included pyrolysis on GAC surface and degradation in air.

- Ultraviolet radiation is a key part to complete the mineralization process.

- In-situ production of ozone avoided nonuniform mix of organic compounds with ozone.

To reduce the secondary pollution of volatile organic compounds generated from adsorbent regeneration, a regeneration method for granular activated carbon (GAC) saturated with chloramphenicol is studied. The saturated GAC is regenerated by microwave and ultraviolet irradiation which radiated from electrodeless lamps activated by microwave. The existence of ultraviolet rays can affect the degradation of chloramphenicol, and it is analyzed by adsorption capacity recovery percentage, mineralisation percentage and the amount of inorganic chloride. The saturated GAC is regenerated in microwave reactor at 2450Â MHz for 10Â min. The mineralisation percentage increases to 37% from 5% when adds the electrodeless lamp into the regeneration reactor. Besides, 83% of the total chloride in chloramphenicol can transform into inorganic chloride. Add ultraviolet radiation in microwave regeneration reactor can enhance the oxidizability of microwave regeneration method. Furthermore, the adsorption ability of GAC can maintain at a high level after five absorption/regeneration cycles. These results show a great potential use of microwave and ultraviolet irradiation to regenerate activated carbon saturated with chlorinated organic compound. This regeneration method can reduce the risk of secondary pollution of chlorinated organic compound during adsorbent regeneration.

114

Journal: Chemical Engineering Journal - Volume 320, 15 July 2017, Pages 264-270