| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 213259 | 462089 | 2009 | 9 صفحه PDF | دانلود رایگان |

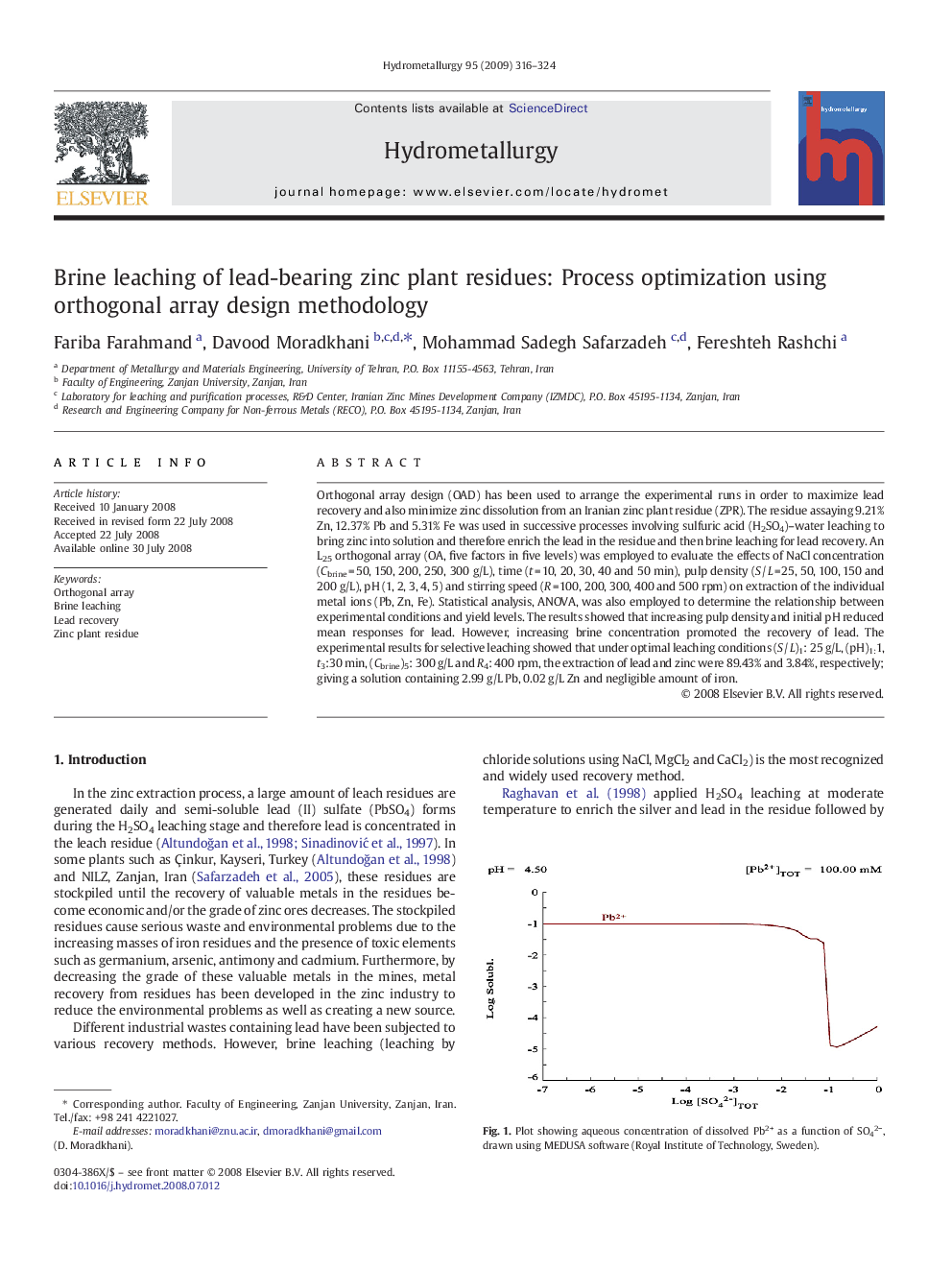

Orthogonal array design (OAD) has been used to arrange the experimental runs in order to maximize lead recovery and also minimize zinc dissolution from an Iranian zinc plant residue (ZPR). The residue assaying 9.21% Zn, 12.37% Pb and 5.31% Fe was used in successive processes involving sulfuric acid (H2SO4)–water leaching to bring zinc into solution and therefore enrich the lead in the residue and then brine leaching for lead recovery. An L25 orthogonal array (OA, five factors in five levels) was employed to evaluate the effects of NaCl concentration (Cbrine = 50, 150, 200, 250, 300 g/L), time (t = 10, 20, 30, 40 and 50 min), pulp density (S / L = 25, 50, 100, 150 and 200 g/L), pH (1, 2, 3, 4, 5) and stirring speed (R = 100, 200, 300, 400 and 500 rpm) on extraction of the individual metal ions (Pb, Zn, Fe). Statistical analysis, ANOVA, was also employed to determine the relationship between experimental conditions and yield levels. The results showed that increasing pulp density and initial pH reduced mean responses for lead. However, increasing brine concentration promoted the recovery of lead. The experimental results for selective leaching showed that under optimal leaching conditions (S / L)1: 25 g/L, (pH)1:1, t3:30 min, (Cbrine)5: 300 g/L and R4: 400 rpm, the extraction of lead and zinc were 89.43% and 3.84%, respectively; giving a solution containing 2.99 g/L Pb, 0.02 g/L Zn and negligible amount of iron.

Journal: Hydrometallurgy - Volume 95, Issues 3–4, February 2009, Pages 316–324