| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 593692 | 1453953 | 2013 | 9 صفحه PDF | دانلود رایگان |

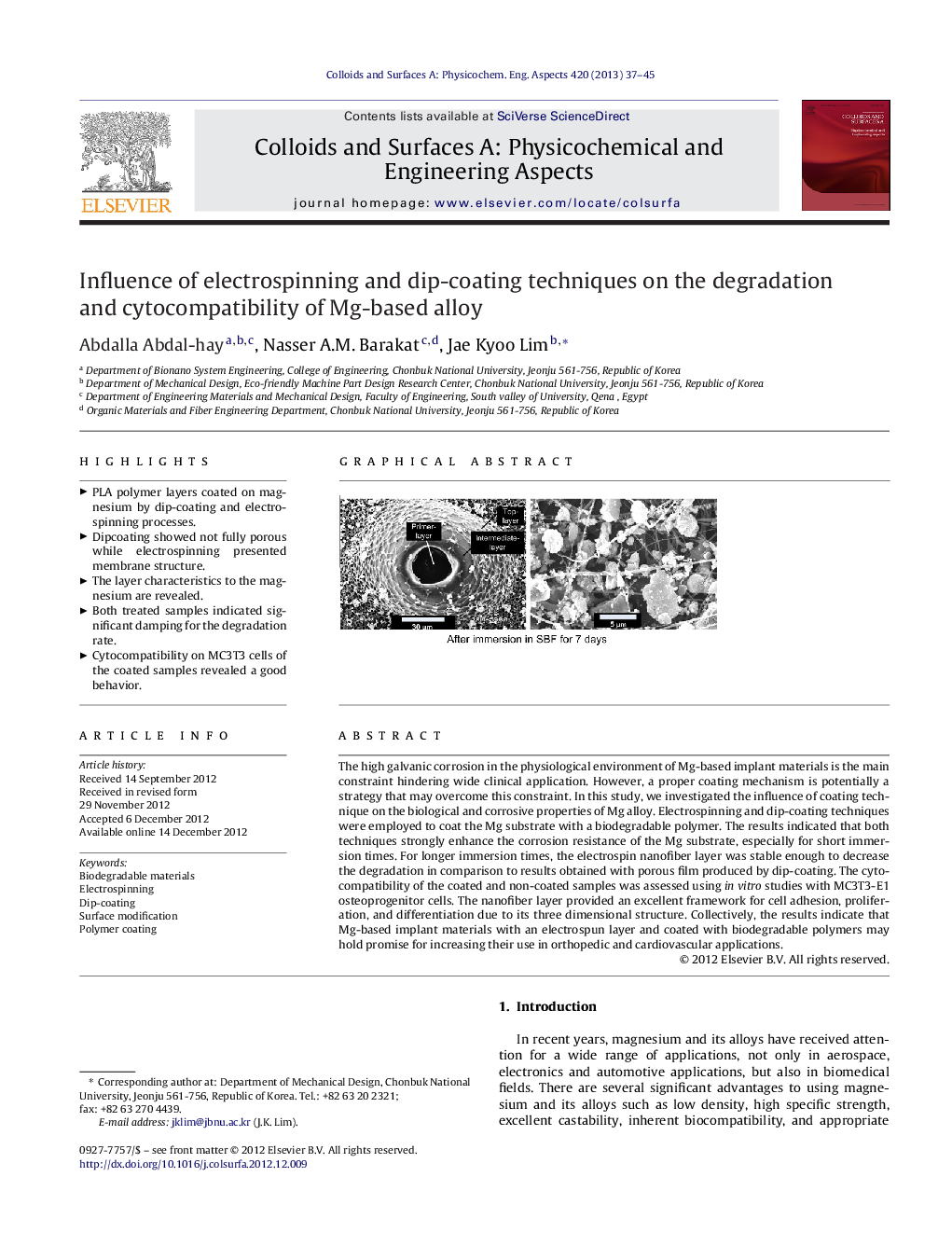

The high galvanic corrosion in the physiological environment of Mg-based implant materials is the main constraint hindering wide clinical application. However, a proper coating mechanism is potentially a strategy that may overcome this constraint. In this study, we investigated the influence of coating technique on the biological and corrosive properties of Mg alloy. Electrospinning and dip-coating techniques were employed to coat the Mg substrate with a biodegradable polymer. The results indicated that both techniques strongly enhance the corrosion resistance of the Mg substrate, especially for short immersion times. For longer immersion times, the electrospin nanofiber layer was stable enough to decrease the degradation in comparison to results obtained with porous film produced by dip-coating. The cytocompatibility of the coated and non-coated samples was assessed using in vitro studies with MC3T3-E1 osteoprogenitor cells. The nanofiber layer provided an excellent framework for cell adhesion, proliferation, and differentiation due to its three dimensional structure. Collectively, the results indicate that Mg-based implant materials with an electrospun layer and coated with biodegradable polymers may hold promise for increasing their use in orthopedic and cardiovascular applications.

Figure optionsDownload as PowerPoint slideHighlights

► PLA polymer layers coated on magnesium by dip-coating and electrospinning processes.

► Dipcoating showed not fully porous while electrospinning presented membrane structure.

► The layer characteristics to the magnesium are revealed.

► Both treated samples indicated significant damping for the degradation rate.

► Cytocompatibility on MC3T3 cells of the coated samples revealed a good behavior.

Journal: Colloids and Surfaces A: Physicochemical and Engineering Aspects - Volume 420, 5 March 2013, Pages 37–45