| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 680444 | 1459973 | 2014 | 8 صفحه PDF | دانلود رایگان |

• Life cycle assessment of algal biodiesel production from bio-crude oil.

• Estimation of energy consumption and greenhouse gas emissions.

• Subcritical water extraction consumes 3–5 times less energy than solvent extraction.

• Production of 1 kg of algal biodiesel could consume as low as 28.23 MJ of energy.

• 1 kg of algal biodiesel fixes about 0.6 kg of CO2.

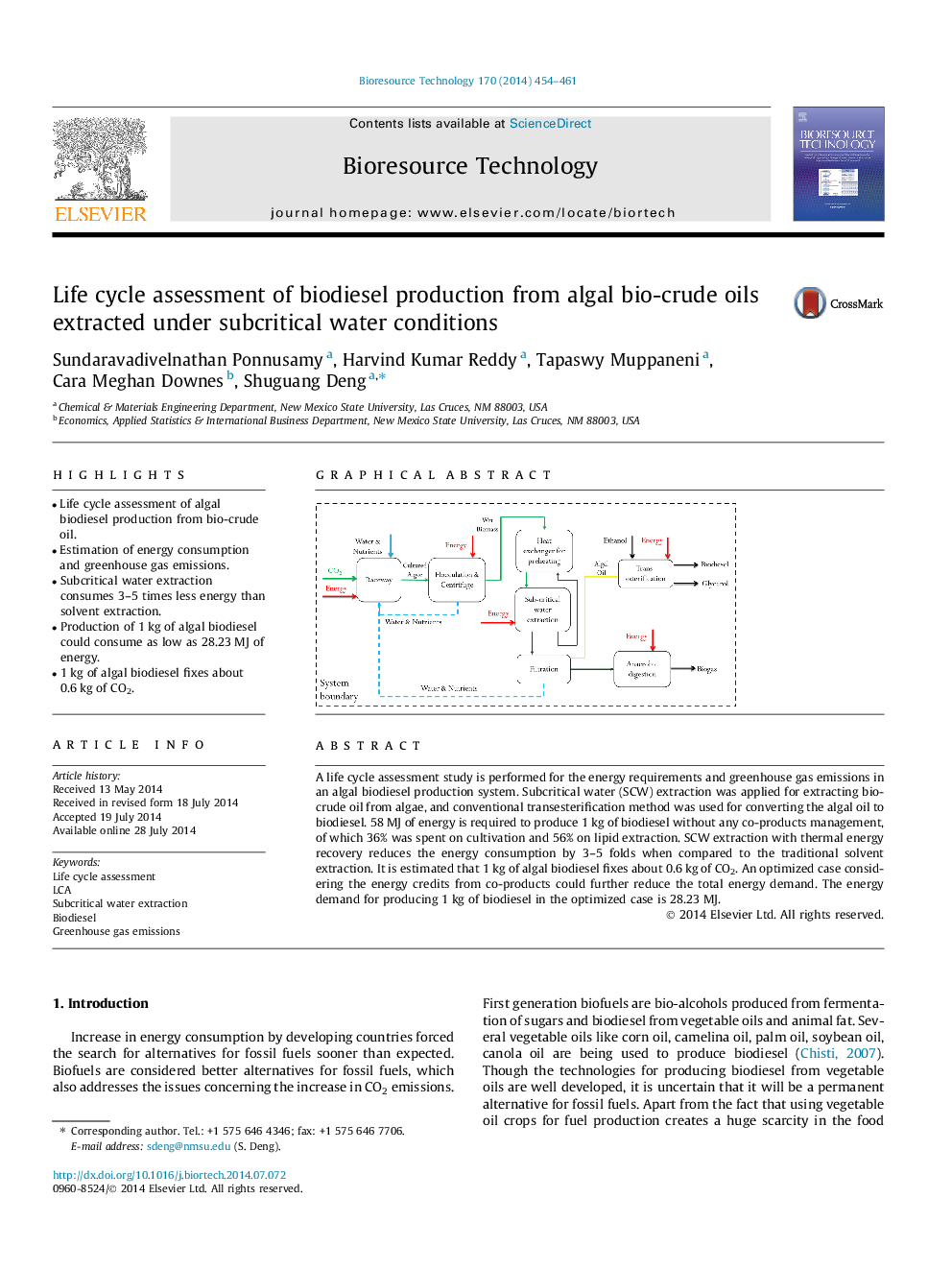

A life cycle assessment study is performed for the energy requirements and greenhouse gas emissions in an algal biodiesel production system. Subcritical water (SCW) extraction was applied for extracting bio-crude oil from algae, and conventional transesterification method was used for converting the algal oil to biodiesel. 58 MJ of energy is required to produce 1 kg of biodiesel without any co-products management, of which 36% was spent on cultivation and 56% on lipid extraction. SCW extraction with thermal energy recovery reduces the energy consumption by 3–5 folds when compared to the traditional solvent extraction. It is estimated that 1 kg of algal biodiesel fixes about 0.6 kg of CO2. An optimized case considering the energy credits from co-products could further reduce the total energy demand. The energy demand for producing 1 kg of biodiesel in the optimized case is 28.23 MJ.

Figure optionsDownload as PowerPoint slide

Journal: Bioresource Technology - Volume 170, October 2014, Pages 454–461