| کد مقاله | کد نشریه | سال انتشار | مقاله انگلیسی | نسخه تمام متن |

|---|---|---|---|---|

| 1664842 | 1518021 | 2015 | 8 صفحه PDF | دانلود رایگان |

• The residual stress in MEMS can be obtained by wafer curvature measurement.

• Using finite element analysis with element birth and death to get thermal stress.

• The intrinsic stress can be acquired by subtracting thermal stress from residual stress.

• Controlling the deposition and annealing temperatures can make polysilicon film flat.

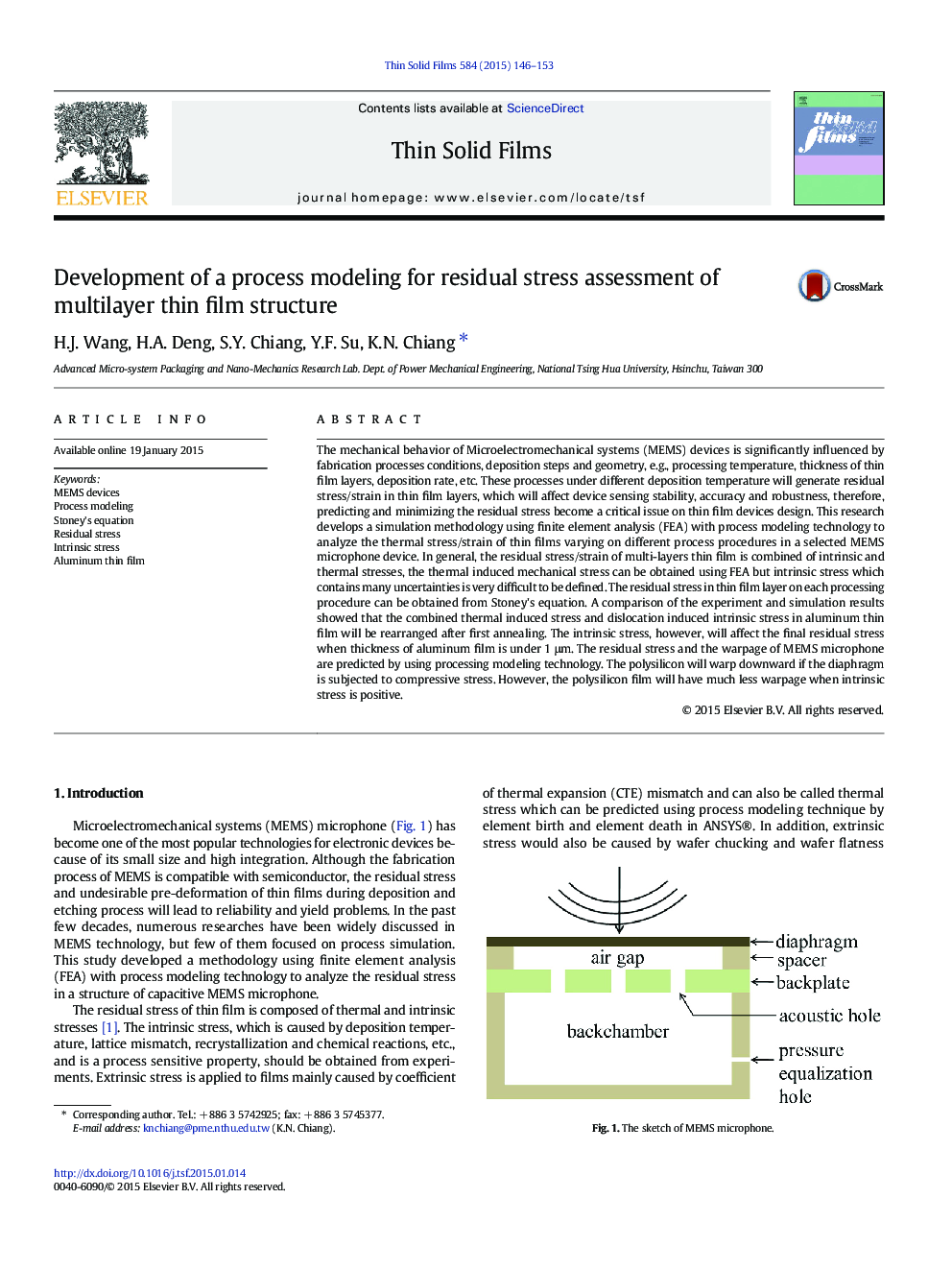

The mechanical behavior of Microelectromechanical systems (MEMS) devices is significantly influenced by fabrication processes conditions, deposition steps and geometry, e.g., processing temperature, thickness of thin film layers, deposition rate, etc. These processes under different deposition temperature will generate residual stress/strain in thin film layers, which will affect device sensing stability, accuracy and robustness, therefore, predicting and minimizing the residual stress become a critical issue on thin film devices design. This research develops a simulation methodology using finite element analysis (FEA) with process modeling technology to analyze the thermal stress/strain of thin films varying on different process procedures in a selected MEMS microphone device. In general, the residual stress/strain of multi-layers thin film is combined of intrinsic and thermal stresses, the thermal induced mechanical stress can be obtained using FEA but intrinsic stress which contains many uncertainties is very difficult to be defined. The residual stress in thin film layer on each processing procedure can be obtained from Stoney's equation. A comparison of the experiment and simulation results showed that the combined thermal induced stress and dislocation induced intrinsic stress in aluminum thin film will be rearranged after first annealing. The intrinsic stress, however, will affect the final residual stress when thickness of aluminum film is under 1 μm. The residual stress and the warpage of MEMS microphone are predicted by using processing modeling technology. The polysilicon will warp downward if the diaphragm is subjected to compressive stress. However, the polysilicon film will have much less warpage when intrinsic stress is positive.

Journal: Thin Solid Films - Volume 584, 1 June 2015, Pages 146–153